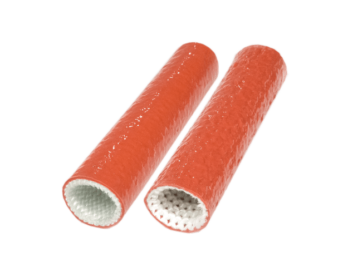

Our high-temperature E-glass fiberglass and amorphous silica sleeves provide unique physical characteristics for better sealing performance at 1000°F (540°C) and 1800°F (980°C) operating temperatures. These high-temperature sleeves are resistant to most acids and alkalis. They’re commonly used to protect hoses, wires, and cables against weld splatter, fire, extreme heat, and molten metal.

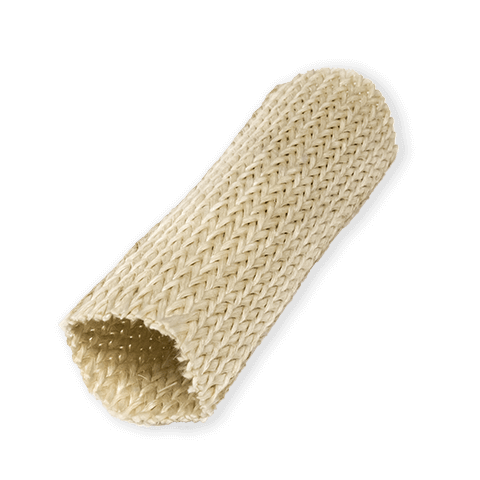

Tetraglas® Fiberglass Sleeves

Tetraglas® sleeves are braided with high-quality E-glass fiberglass yarns and provide flexibility, durability, and thermal containment. They will not burn and remain suitable for use in applications with temperatures up to 1000°F (540°C). Our braided fiberglass sleeves can be heat treated or coated with vermiculite, PTFE, graphite, or acrylic saturant.